With almost 4 decades of working in the manufacturing industry, you learn a lot about processes and materials. How things are made and what is involved in the process.

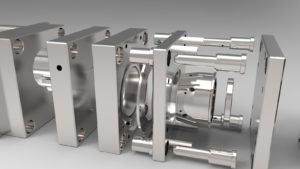

Peter has been involved in the reproduction of old car and vintage motor cross bike parts. This is reverse engineering at its best. Having to work out how it was made, which process was the part made in and what materials where used. In the case of the HQ Holden sun visor the original part was made from a foam that used a blowing agent made from CFC’s. Today manufacture with CFC’s has been banded but the RIM process used was still available. The issue was how do we develop this product to look and feel that same as the original. In the original they used an in mould coating that was also not available today.

Through careful research we were able to develop the process using a foam that was self skinning and an in mould coating that would be suitable to provide the desired result. This method of research and know how was used on many other components throught the time Peter was involved in the company..